High Pressure Industrial Rubber Petroleum Hose for Bop API 16D

Basic Info

Model No.: BH

Product Description

Model NO.: BH

Capability: Heat-resistant Rubber Hose

Tube: Modified Nitrile

Working Temperature: -40-+100

Certification: API Spec 16D

Specification: 1/4"-2"

HS Code: 8431431000

Material: Nitrile Rubber

Color: Black

Reinforcement: Multiple Layers of Textile Fabric and Steel Cable

Working Pressure: 35MPa

Trademark: ORIENTFLEX

Origin: Hebei, China

High Pressure Industrial Rubber Petroleum Hose for Bop API 16D

5,000psi W.P. - 10,000 psi Test-15,000 Minimum Burst

Certification/Standards:

API Spec 16D--ISO 14693

Recommended For:

Blow-out preventer (BOP) systems requiring high pressure, high temperature and flame resistant control lines certified to API 16D.

Armored hose assemblies with flame resistant cover withstand minimum 1300°F (+700°C) flame temperature at working pressure for 5 minutes without failure.

Tube: Modified Nitrile. Black.

Reinforcement:

Multiple layers of textile fabric and steel cable, with one layer middle rubber placed between cable layers.

Cover:

Fire resistant, rubber cover, stainless steel armored to handle abrasion, corrosion, cutting, gouging, oil and weather.

Couplings:

Crimped couplings with over-ferrule fire protection.

Temperature:

-40°F to +212°F (-40°C to +100°C) continuous service.

Options:

Accessories such as API 16D quick connector, self-sealing union and exterior armor to protect hoses against extreme environmental damage are available upon request.

Specification:

| Hose ID | Hose O.D. | Working Pressure | Min. Bend Radius | Weight | Max. Hose Length | ||||||

| (In.) | (mm) | (In.) | (mm) | (psi) | (MPa) | (In.) | (mm) | kg/m | lb/ft | ft | m |

| 1/4 | 6 | 0.77 | 20 | 5000 | 35 | 4 | 102 | 0.66 | 0.37 | 330 | 100 |

| 3/8 | 10 | 0.93 | 24 | 5000 | 35 | 5 | 127 | 0.77 | 0.52 | 330 | 100 |

| 1/2 | 13 | 1.05 | 27 | 5000 | 35 | 7 | 178 | 0.98 | 0.63 | 330 | 100 |

| 3/4 | 19 | 1.38 | 35 | 5000 | 35 | 9.5 | 241 | 1.64 | 1.05 | 200 | 60 |

| 1 | 25 | 1.67 | 42 | 5000 | 35 | 12 | 305 | 2.62 | 1.77 | 200 | 60 |

| 1 1/4 | 32 | 2.11 | 54 | 5000 | 35 | 16.5 | 419 | 3.94 | 2.67 | 200 | 60 |

| 1 1/2 | 38 | 2.41 | 61 | 5000 | 35 | 20 | 508 | 4.59 | 3 | 200 | 60 |

| 2 | 51 | 2.96 | 75 | 5000 | 35 | 25 | 635 | 8.53 | 5.73 | 200 | 60 |

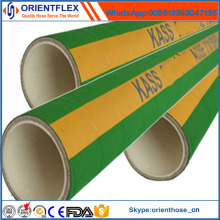

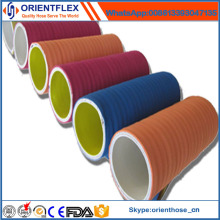

Product Show:

Company Information:

ORIENTFLEX is a professional manufacturer of rubber and plastic hose in Hebei, China.

Established in 2006, OrientFlex have more than 240 experienced workers, own a strong

R & D team, including 16 experienced engineers.

Advantage:

1). Advanced production equipment

2). ISO 14000 / ISO 9000 / Quality certificate

3). Strict quality inspection, Strong R&D team

4). Environmental friendly without pollution

5). 10 years manufacturing experience, strong and experienced export team

ORIENTFLEX has a strong sales and service team of 20 people, with more than five years experience in foreign

trade, to provide professional services for customer.

ORIENTFLEX has advanced production facilities, including 13 high-speed fiber braid machines,15 high-speed steel

wire braid machines,2 steel wire spiral production lines.45 PVC Hose production lines.We have introduced VP brand

Industrial Hose production line from Italy and Maillefer extrusion line from Switzerland.

ORIENTFLEX has strong quality control team,we set up advanced laboratory.Before mass production,we test each

batch raw material.After production,we test each hose to guarantee 100% qualification.

ORIENTFLEX has three warehouses.

Production process:

Advantages:

• Germany Lanxess HNBR as raw material.

20% H2S and 80% oil based mud.

Survive the extreme oilfield application requirements and has been no quality complaint for 5 years.

• Stainless steel 316L used as armored jacket

Factory Workshop:

• SEJIN MACHINE from Korea.

Suspension difference<70 MM, and the international standard is 120 MM.

• Mitsubishi electric control braiding machine.

High accuracy data collection, real-time braiding angle monitoring and correction

Pressure Test:

Each hose is tested at 10000psi for 15 minutes. Pressure test graph, test certificate and letter of conformance are issued for each hose.

Packing:

After finishing the hose production, we will pack the hose.

In general, the packing will use woven bag and plastic film.

Special packing is available according to customers' requirements.

Certificate:

All Product Meet The Standard Of ISO And The Requirement Of API.

Contact Us:

TEL:86-311-68008301 FAX: 86-311-68008302

Mobilephone:008613393047135

Add: No298 Zhonghua North Street, Shijiazhuang, Hebei, China

More rubber hose products information Please visit:http://www.orientrubber.com/

Contact us if you need more details on Industrial Hose for Bop. We are ready to answer your questions on packaging, logistics, certification or any other aspects about High Pressure BOP Hose、Petroleum Hose. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Oil & Gas Hose > BOP Hose

Other Products

Hot Products

Evacuation and Material Handling Air Seeder HoseHeavy Duty Concrete Pumping Rubber HoseThermoplastic Hydraulic Hose SAE100 R7/SAE 100r7 DistributorHigh Temperature Flexible Chemical HoseRubber Smooth Flexible Air HoseFlexible High Pressure Rubber Water Suction Hose PipeFlexible High Pressure Washer Hose2016 High Grade Rubber Hydraulic Paint Spray Duct HoseChina Rubber Hydraulic Hose SAE 100r2EVA Flexible Hose for Vacuum CleanerManufacturer Customized Product Extrusion Profile (OKAWA-07)16*21mm High Flexible Drain Hose for Air-ConditionerHigh Flexible EVA Hose for Swimming PoolHigh Quality EVA Vacuum Cleaner HosePVC Reinforced Hose with UV ResistantPVC Conduit Corrugated Hose for Protection Wire Cable